What does HRC stand for?:

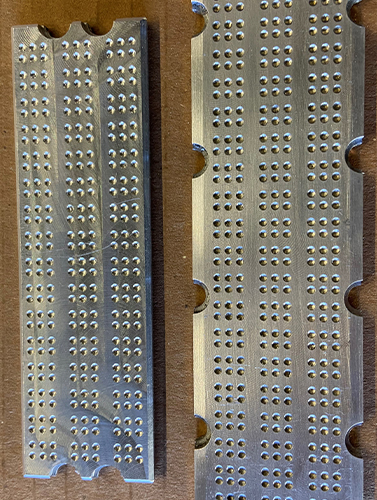

Rockwell hardness: Hardness of a material measured by the depth of the imprint left by a conical or spherical indenter under a defined load. (We use scale B [symbol HRB] for materials with medium hardness and scale C [symbol HRC] for hard materials.

The most used references:

HRC 38 / HRC 42: 1mm

HRC 50: 1.35 mm particularly indicated in the case of die-cut shapes with integrated embossing, requiring the presence of large embossing blocks. Perfectly suitable for different types of cardboard thicknesses.

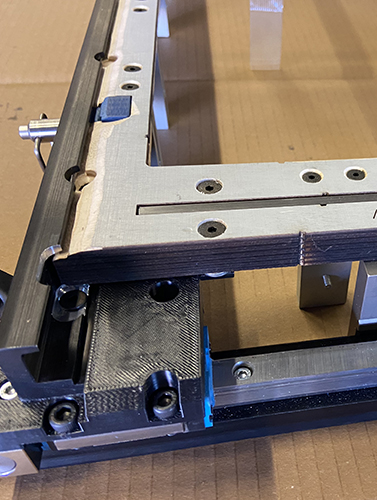

Our machine park: Within the VACHER group, we have 4 latest generation digital milling machines

How does this product behave compared to the PERTINAX counterpart?

In pertinax, the depth of the channel for creasing is equal to the thickness of the cardboard.

In Pertinax mode, throat wear, edge wear crumbles after 1,000 sheets.

The outline of a case or final packaging is less marked.

Pertinax thickness = cardboard thickness.

A game of pertinax is renewed on average 2 to 3 times depending on the volume of the number of passages, and the pressure exerted during the strikes.

STOP preconceived ideas: The plate engraved in the economic whole of a project can prove to be more profitable than the PERTINAX system, beyond a gain in quality.

Features :

- Stainless steel or steel depending on the hardness (HRC)

Advantages :

- Time saving from the 1st setting on the machine, no positioning studs to put in place.

- Hold of attachment points +++

- Better quality of inverted folds, aesthetic and functional final rendering

- Identical quality from the first sheet to the last sheet, with the same creasing quality

- Quality of the final product (packaging)

- Resistance to wear avoiding the renewal in “emergency” mode of counterparties

- Avoid monitoring the level of wear instead of the Pertinax counterpart

Benefits:

- Long product life

- Productivity gain

- Gain in speed

- Easy stock management

- Better quality of inverted folds, aesthetic and functional final rendering

Quality of the wood used:

Depending on the project, we work on 2 types of wood:

- DRYWOOD , plywood which offers perfect stability and good tolerance to humidity.

- 3D , plywood that offers perfect stability, good hold of the nets, and exceptional resistance to humidity.

All our expertises

All our expertises